Bearing failures is one of the repeated challenges that industries continue to face. Grease alone caters to the lubrication requirements for approximately 80-90% of the bearings. It plays a crucial part in the course of predictive maintenance, on the load conditions of the machinery system, and in paving the way for accelerated wear conditions.

Grease analysis is a complex task that involves two challenges. The first challenge lies in identifying the correct sample that is representative of the actual condition of both the grease and the bearing. The second challenge gets a little tricky because it requires analysis of different data collected from different parts of the system where the grease is in service.

By performing a grease analysis, we help our customers improve the reliability, performance, safety, and therefore the profitability of their assets and equipment.

At The Viswa Group, we understand the impact machinery wear and failure can have on an organization’s bottom line.

Having an extensive track record optimizing asset life, safety, and performance, we are well-positioned to perform advanced grease sampling and analysis for the Marine Industry, Petrochemical Industry, and Emission Compliance Solutions.

As experts in the field of testing, we have helped over 750 clients and 9,000 ships across industries achieve beyond what they thought was possible. At The Viswa Group, our customers are guaranteed to benefit from:

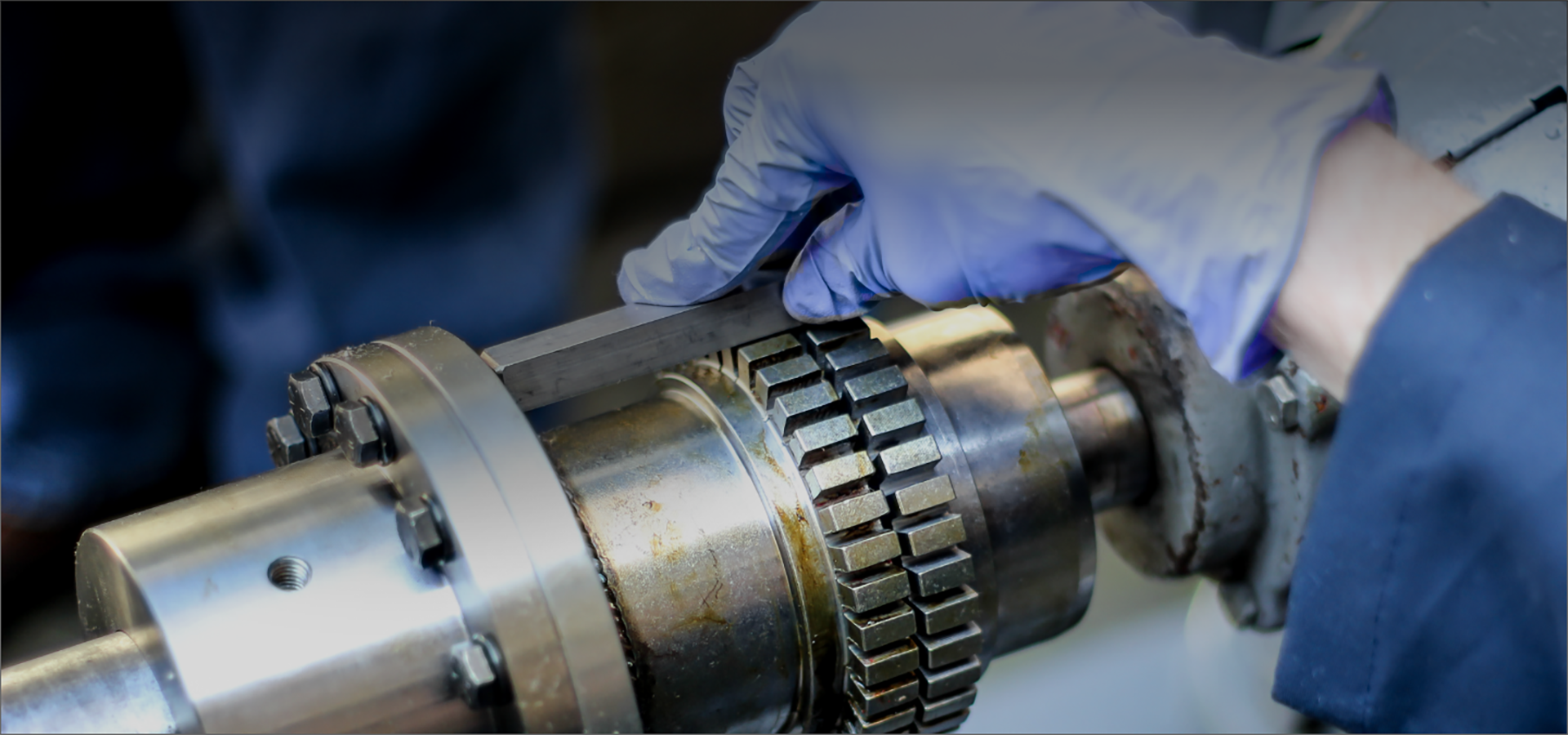

Our team of tribological experts examine the suspended machinery, grease sample, and other solid contaminants first-hand to collect evidence of any contamination, wear, and degradation. We then perform standard grease tests and performance tests to get to the root cause behind the wear and failure, providing our customers with custom recommendations to help them get back to their operations without disruptions.

Access our expert advice whenever and wherever.

Download Now