During the 2009 Hong Kong Convention, the International Maritime Organization (IMO) introduced The Inventory of Hazardous Materials (IHM) to ensure safe recycling of ships and minimize health risks onboard. As a result, all ships weighing over 500GT are required to carry the Inventory of Hazardous Materials.

IHM surveys provide ship owners, crews, engineers, managing agents, and workers with an in-depth report of all the hazardous materials on board the vessel. This report makes it easier to stay up-to-date and in compliance with IMO regulations.

The main materials that the IHM survey covers are asbestos, PCB’s, TBT’s, ODS and PFOS. Other materials such as PBDE, PBB, Mercury, and Lead may be determined later in the report.

There are several parts and conditions to the IHM Survey. Part 1 Tables A and B are for newly built and active ships. Parts II & III Tables C and D are aimed towards vessels carrying out major refurbishment works or vessels that are sent for recycling in accordance with the Ships Recycling Regulations (SRR).

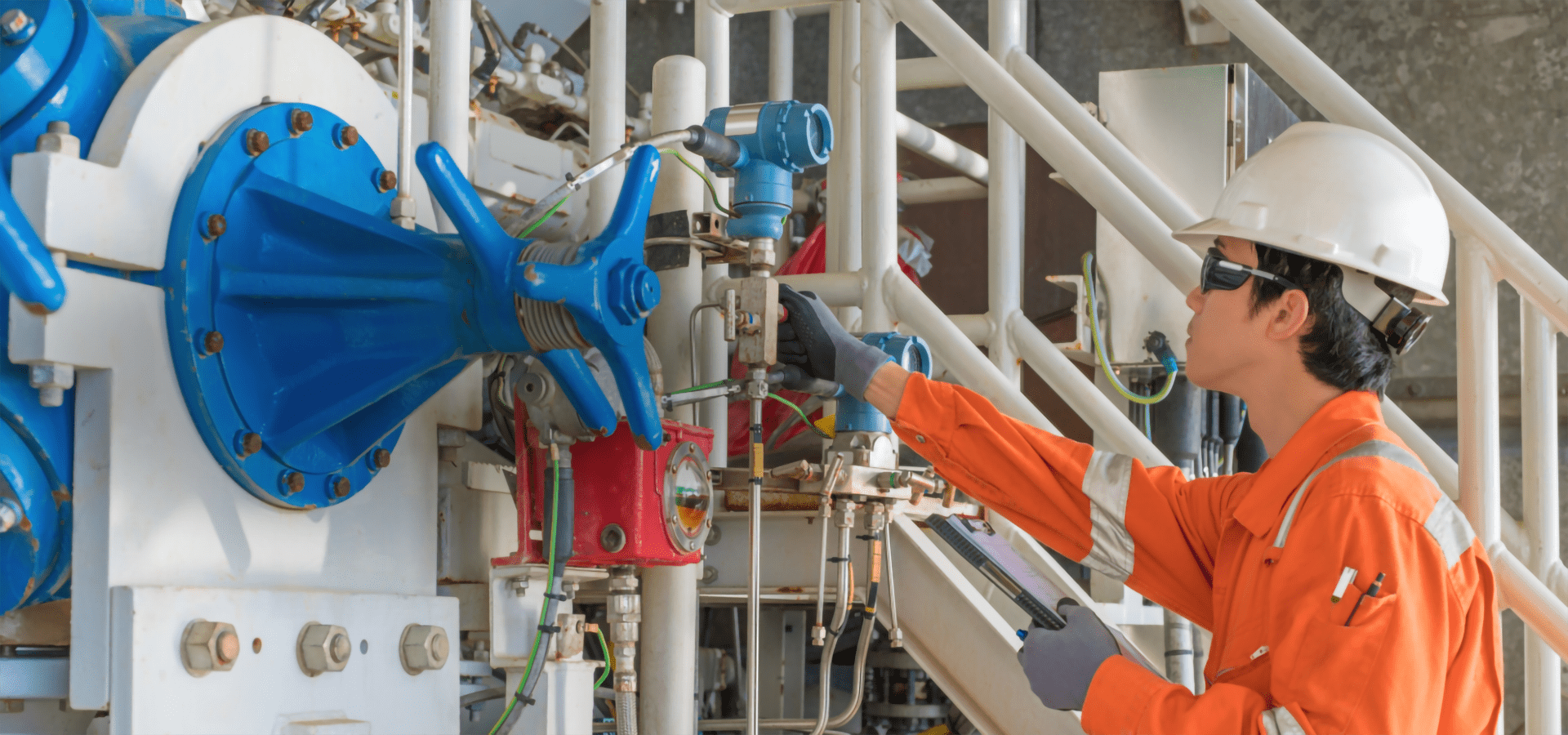

The Viswa Group’s highly experienced Hazmat experts provide Hazmat inspection, consultancy, and management services to the Marine Industry.

As per IMO regulations, the IHM must undergo annual verification to ensure that it’s kept up-to-date. The vessel also needs to be re-surveyed every five years to ensure compliance.

The Viswa Group’s condition monitoring and surveying teams help:

IHM surveys can take place while the vessel is at sea or in port. With our offices strategically placed worldwide, our IHM Survey teams are able to meet and leave the vessel at most ports internationally.

For more information contact us at [email protected]